|

- Mass produced.

- Modular construction.

- Space saving, future oriented design.

- Single and double girder models, capacities from 2 to 50 tons.

|

- Uniform quality

- Optimally matched components

- Greater clearance, modern

appearance.

- Suitable for a wide variety of

applications.

|

Quality Standards |

EMH is a member of Crane Manufacturers Association of America (CMAA).EMH is certified to ISO 9001:2008 standards for design, manufacturing, installation, and servicing of overhead cranes. |

Hoist design conforms to all applicable national and local standard standards.You are dealing with an organization that continually reviews its management processes and meets internationally accepted standards. |

6 to 1 Hoist Speed Ratio |

The 6 to 1 ratio will provide better maneuverability, and using the slow speed can easily result in a fraction of an inch movement up or down. This will allow delicate positioning and precision spotting. In addition, the design is not load sensitive as the older variable speed control systems. |

- Lifting and lowering can be

executed safely and precisely

- Saves time

- Reduces load damage.

|

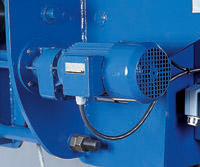

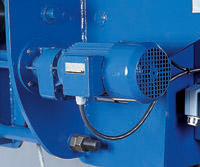

Severe Demand Hoist Motors |

Our pole-changing squirrel cage hoist motors are designed and built for operations that require frequent inching and spotting. They are totally enclosed and fan cooled and designed exclusively for crane and hoist duty. These 60 minute TEFC “F” insulated motors efficiently dissipate heat. Large braking surface ensures fast, precise stopping of load under all load conditions. |

- Trouble Free Service

- Longevity

|

Trolley Drive

(Single Girder Hoists) |

Consists of pole-changing squirrel cage gear motor. Class “F” insulation. Integral DC disc brakes specially designed for crane service. Low torque, high inertia drives.Variable Frequency Drive standard. |

- Smooth acceleration without

load swing.

- Long, maintenance-free life.

|

Trolley Drive

(Double Girder Hoists) |

Consists of heavy duty pole-changing squirrel cage gear motor. Class “F” insulation. Integral DC disc brakes specially designed for crane service.Low torque, high inertia.Variable Frequency Drive standard. |

- Smooth acceleration without

load swing.

- Long, maintenance-free life.

|

Trolley Wheels

(Single Girder Hoists) |

Wide, large diameter, machine tool quality steel wheels and drive pinions. |

- Fit nearly any flange width or

beam style.

- Less flange bending stress

reduces beam size.

|

Trolley End Trucks

(Double Girder Hoists) |

Direct drive with rotating axle. Articulating end truck. Sealed lifetime lubricated bearings. Hardened wheels. |

- Reduced maintenance.

- More efficient power transmission.

- Longer life.

- Three-wheeling eliminated.

|

DC Rectified Disc Brakes |

Our motor brakes are DC rectified magnet actuated disc brakes and are automatically applied in the event of a power failure. These self-compensating and virtually maintenance free brakes are provided with asbestos-free, non-polluting linings. |

- Operate millions of times

without adjustment

- Reduce service requirements

- Provide longevity

|

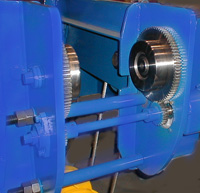

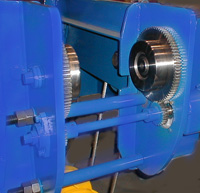

Gear Trains and Bearings |

The gear train and bearings are lifetime lubricated and our gear trains are hardened and polished Class 12 helical gears. Our gear trains afford an extremely low decibel level during operation and the helical gearing is manufactured to exacting tolerances, resulting in exceptional longevity. |

- Relieve personnel from time

consuming maintenance

procedures

- Years of trouble free operation

- Meets or exceeds OSHA noise

regulations.

|

Limit Switches |

All wire rope hoists are equipped with two upper and one lower geared limit switch. Easily adjustable, this switch brings the load to a positive stop in both hoisting and lowering directions. |

- Provide safe operation

- Eliminate slack cable conditions

- Prevent rope from unraveling

|

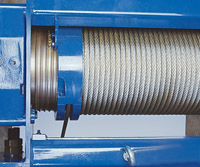

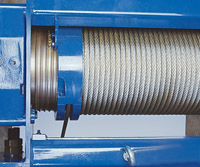

Wire Rope and Wire Rope Guide |

This assembly is of rugged design and able to withstand severe industrial use. It keeps the rope in contact with the drum grooves even under slack rope conditions. |

- Provides longer life

- Requires less maintenance

- Safer for operator

- Reduces wear

- Prevents rope from being

unbraided and cut

- Protects operator from injury

|

Quick Disconnect Plugs |

Pre-tested multi-pin plug and socket connections are used for motor power connections, pushbutton control cable, connections to control boxes and festooned terminations. The quick disconnects are of the highest quality, sealed from dust and moisture and vibration proof. |

- Save time

- No electrician needed to

disconnect components

|

Optional Overload Limit |

Highly sensitive electro-mechanical overload device is a standard option. Prevents hoist from lifting loads larger than capacity. |

- Prevents damage to hoist

- Provides longer life

- Lessens maintenance

requirements

- Makes operation of hoist safer

|